This is where I get much more concerned with accuracy. The pommel has to serve several functions. It hold the pommel fins; one of which is the latch for the chamber reveal. It holds the twist lock mechanism, and it also serves as sound openings for the speaker. I have to make very sure that all my cuts are good, as I don't want to start over with this piece.

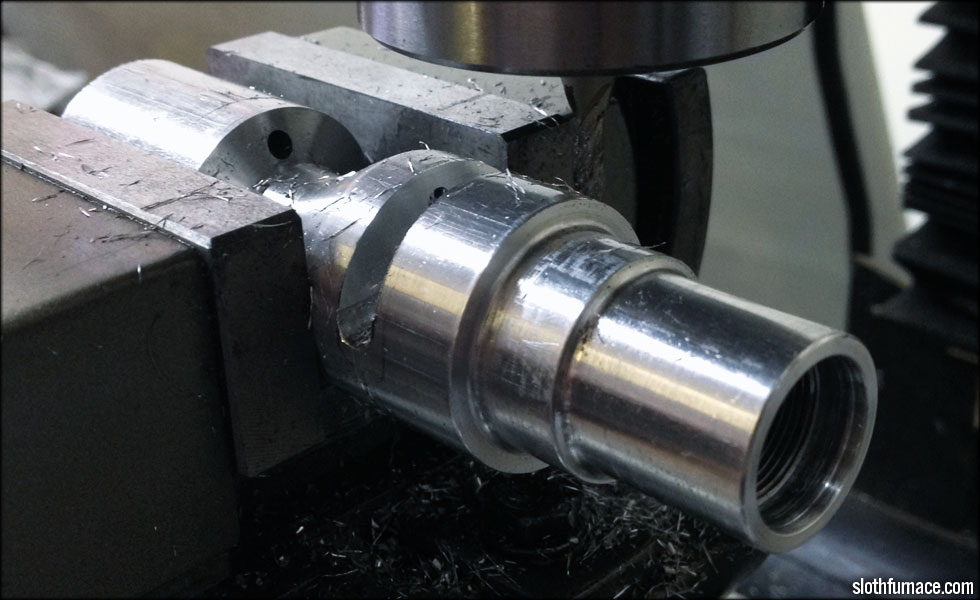

This cut is the first pommel fin saddle slot. I have to make it in several passes at more than one depth, as the base contour of the fin saddles isn't straight.

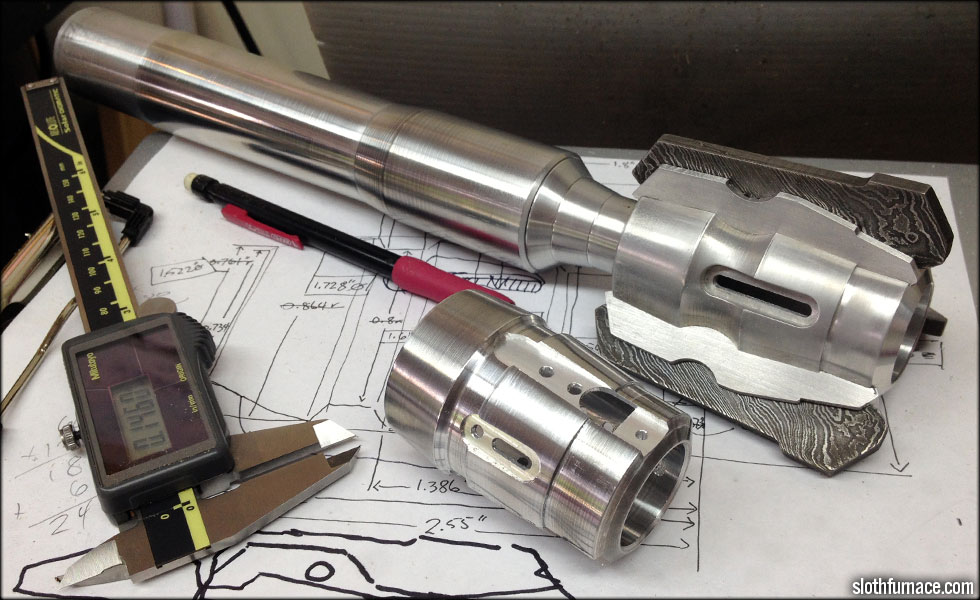

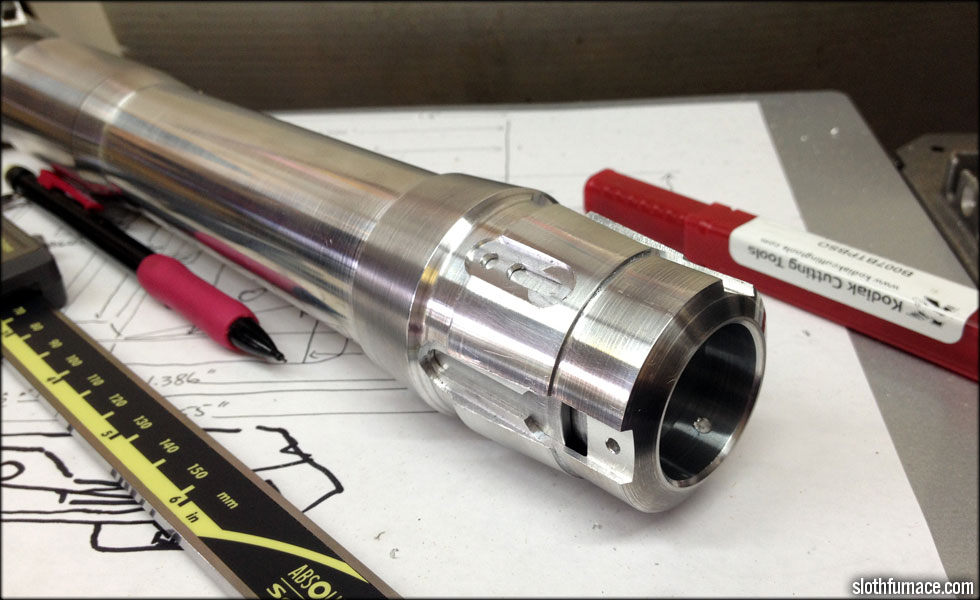

Here is the pommel mostly machined. Holes for sound vents, holes for screws that attach the pommel to the hilt handle, holes for the screws for the fin saddles, the latch slot where the latch tooth will drop into, and also the twist lock bumper hole.

Now that the pommel is on the back of the hilt, I can mark the holes I need to cut into the back of the hilt handle.

Starting work on the crystal chamber, I found these pre-made 1" aluminum discs. That saves me a LOT of time cutting them from sheet, like I would normally do. I'll bore them out for the crystal, and drill the mounting holes and shape the top contour.

Before I get too far with the chamber fins, I need to get the chamber separated. That's a set of cuts I have been dreading, because they have to be done correctly, or the entire chamber slug will have to be re-done. Thankfully, the cuts are going well. A new collet set for the milling machine and a sharp bit means a good steady, controllable cut.

This site is part of the nonentity network. Not associated with LUCASFILM LTD.™ or any LFL Ltd.™ Film or Franchise.